Gusrom places a high priority on the ongoing development of our employees. Recently, our staff participate in a comprehensive training program focused on denture production. The training is designed to deepen our employees’ understanding of the complexities of high-quality denture production & the need of dental technicians.

The training begins with an overview of the various denture types. Employees learn about the materials and designs used in different denture creation. New employees take the opportunity to feel different digital dental solution of Gusrom.

Gusrom employees are taking denture type training.

A large part of the training allows employees to experience the denture production process firsthand. Employees participated in the following key aspects:

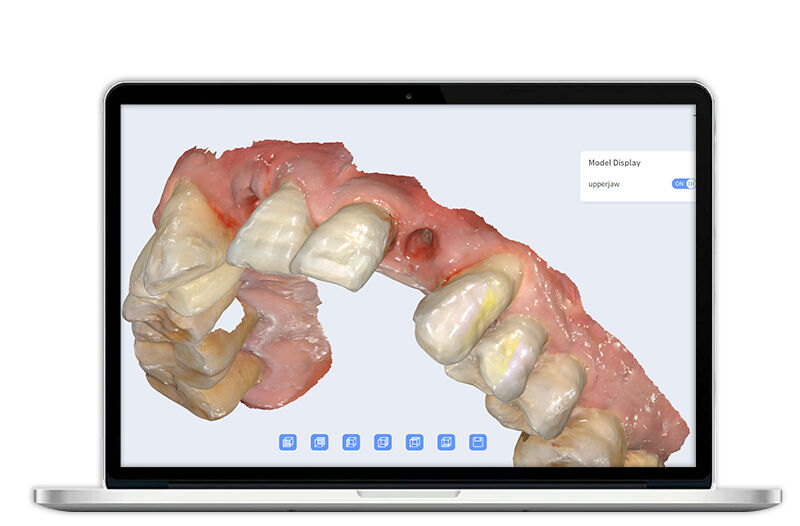

Denture Design(CAD process): Employees learn how to design dentures by digital design software under the guidance of our dental technician.

Machine Operation: Training includes practical sessions on operating dental milling machines and other equipment to ensure precision and quality in denture manufacturing.

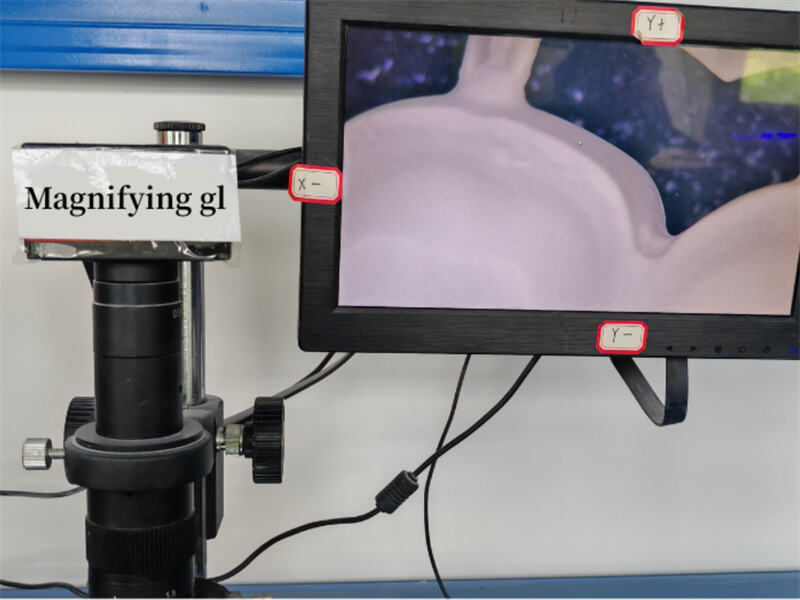

Quality Inspection: During and after the fabrication of the denture, Staffs follow the quality inspection department to inspect the Gusrom zirconia block and the fabricated denture. Our employees place Gusrom zirconia disc after milling under a magnifying of 260 ×, and the edges of the zirconia block could be seen without defects. New staffs experience better edge stability of Gusrom zirconia blank more intuitively. The enlarged images are shown below↓↓

A well-trained team is better able to understand the complexities of denture production, resulting in higher-quality customer service. Driven by technological innovation, product excellence, and service commitment, Gusrom upholds “a customer-centric philosophy” to continuously create value for users.

Hot News

Hot News2026-01-23

2026-01-20

2025-09-30

2025-05-16

2025-05-10

2025-05-01