In the ever-changing world of dentistry, Gusrom is a brand you can trust with a strategy that keeps pace with the times. Gusrom specializes in high-performance dental zirconia, which is designed to meet the precision machining needs of dental laboratories. Here are the reasons why you should choose Gusrom CAD/CAM zirconia for your dental solution.

Gusrom CAD CAM zirconia series,for different dental solutions.

Why Gusrom Zirconia disc different from others?

Precise particle dimension control: We perform rigorous particle size testing down to 0. 01 nanometers. And the powder purity is required to reach 99. 9%. This ensures our zirconia blocks have excellent processing properties, resulting in sophisticated dental restorations.

4D X ML zirconia block made of 100% zirconia powder, it meets the highest standards for dental materials.

Automated zirconia production: Our automated zirconia production process ensures consistent quality. The stability of Gusrom zirconia reduces the rework in dental laboratories. The factory pass rate reached 100%. This production also ensures timely delivery, allowing you to meet the requirements for rapid denture production.

Innovative powder formula: Our dental zirconia is developed by experts in ceramic research with over 10-year experience. The innovative formula achieves high-translucent incisal area, coming closer to natural teeth. In addition, our product has minimal shades difference and does not require extensive dyeing.

The process of Gusrom zirconia production

Bidirectional Dry Pressing: We use bidirectional dry pressing technology, and the weight accuracy is controlled at 0. 01 grams by the automated machinery. This increases the density of the zirconia block and makes it less prone to cracking.

Cold Isostatic Pressing: Our process applies uniform pressure from 4 directions. This ensures a stable and evenly distributed structure of the zirconium oxide(ZrO2) particles, resulting in a dental restoration with a finer particle size and a more homogeneous structure.

Pre-sintering process: The temperature difference in our pre-sintering process can be controlled within 5-10°C. This precision ensures that our products reach the ideal 3-point bending strength required for dental restorations.

Advanced Forming Technology: During the forming stage, we use non-contact processing technologies such as laser and electron beam processing. This improves the precision and surface quality of zirconia teeth.

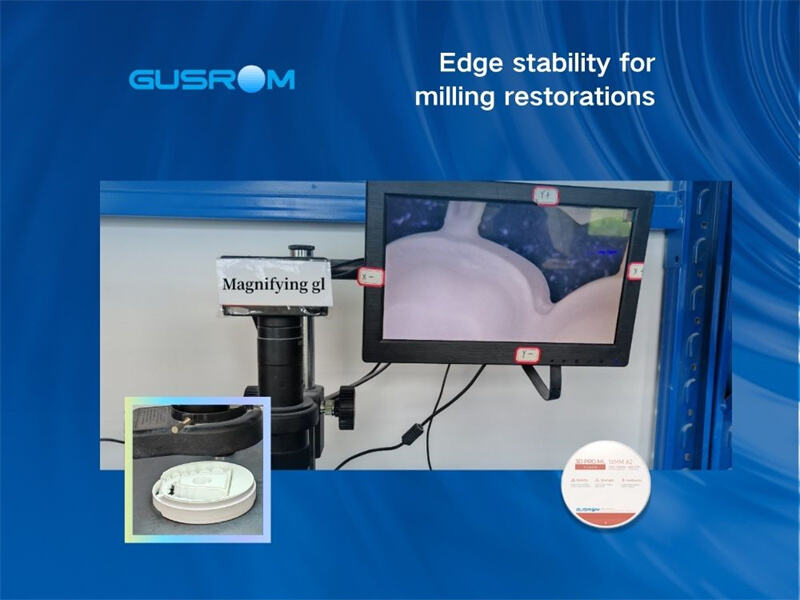

Strict Quality Control: Every step of our production process is subject to strict quality control. Our zirconia blocks are sent to the R&D laboratories and dental laboratories for testing every day. Processing performance are evaluated to ensure the highest standards.

Gusrom adopts a multi-stage densification process, to ensure that each piece of zirconia blocks from raw materials to finished products achieves nanometer-level precision control. Gusrom dental zirconia block helps dental technicians to embrace the era of digital dentistry, achieving fabricating highly-aesthetic and high-precision dental restorations.

Hot News

Hot News2026-01-23

2026-01-20

2025-09-30

2025-05-16

2025-05-10

2025-05-01