Porcelain ovens have been a staple for hundreds of years in producing lovely and durable porcelain objects. These furnaces were simple, and wood- or coal-fired. They were used to create bowls, vases and other decorative objects. Over time, people developed additional techniques to improve porcelain furnaces.

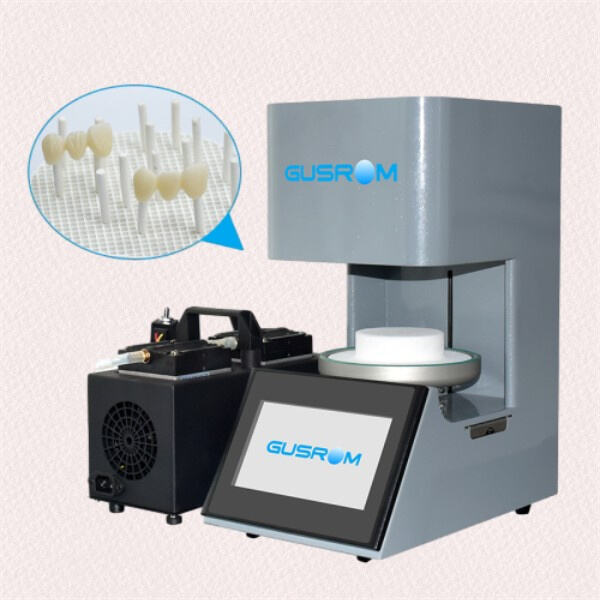

Porcelain ovens are the lifeline for the dental profession. Dentists also need porcelain furnaces to manufacture crowns and bridges among other products for their patient. But these objects should be sturdy, durable and realistic. Dentists are able to achieve all these, and more, using porcelain furnaces.

Dentists can also make patients customized dental prostheses that not only fit comfortably but also last longer using porcelain furnaces. This more or less increases the comfort and performance of the dental prostheses, resulting in not only an improved oral health, but also a better dental health in the patients. The introduction of porcelain furnaces in the dental field has enabled us to produce high quality dental prostheses with less effort.

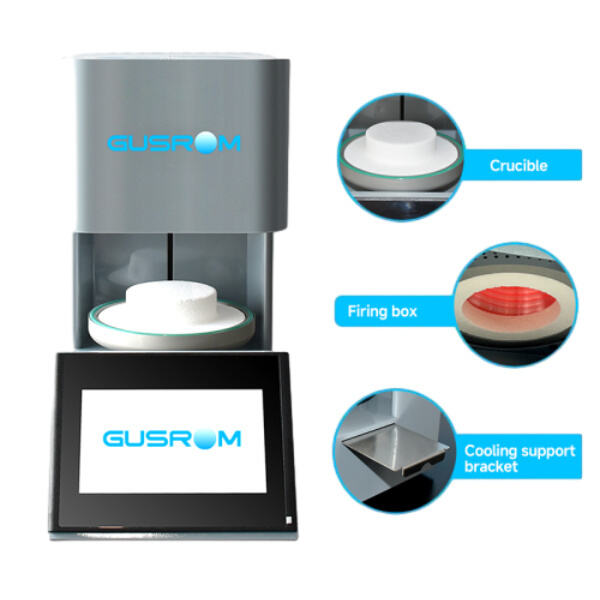

Modern porcelain ovens have a number of elements that are used in conjunction with each other to make strong and beautiful porcelain items. These elements are the heater, the temperature limiter, the ceramic chamber, and the cooler. All of these parts are essential pieces of the porcelain-powder-production puzzle.

The heater heats the furnace to the required temperature. The temperature control system members operate to control the temperature in the furnace chamber, so that the porcelain pieces can be uniformly heated. The ceramic chamber is where you put your porcelain items to heat, while the cooling system cools down your items when you are finished.

Regular maintenance is important to keep your porcelain furnace in excellent working order. Regularly clean the furnace to eliminate dust or debris that could be interfering with efficiency. Confirm the heating element and temperature control system are functioning normally. When you see something is wrong with your porcelain oven, whether it is heating unevenly or not keeping temperature properly, it is important to troubleshoot the issue and correct it right away.

For your laboratory, there are several advantages to having a good-quality porcelain furnace. A premium porcelain furnace is faster, more dependable, more cost effective and helps you produce the best porcelain results. It also can save you money on maintenance and repairs over time. And, you'll get perfect results because a fine porcelain furnace will guarantee the porcelain items that you make are of high quality and resistant to wear and tear.