Dental lab porcelain furnaces are unique instruments used in dental laboratories for fabricating porcelain crowns, bridges and other dental prosthesis. These machines are crucial in the production of such dental devices because they can heat porcelain to extremely high temperatures, making it possible to mold the material to the precise shape required for an individual patient’s mouth.

How Dental Lab Porcelain Furnaces Work Dental lab porcelain furnaces are designed to have heating elements that will increase the temperature within the furnace to a predetermined point. The dental porcelain is put into the furnace and fired to firing temperature. When the porcelain is dry, it can be molded, cured and cooled to form a custom dental device for the patient.

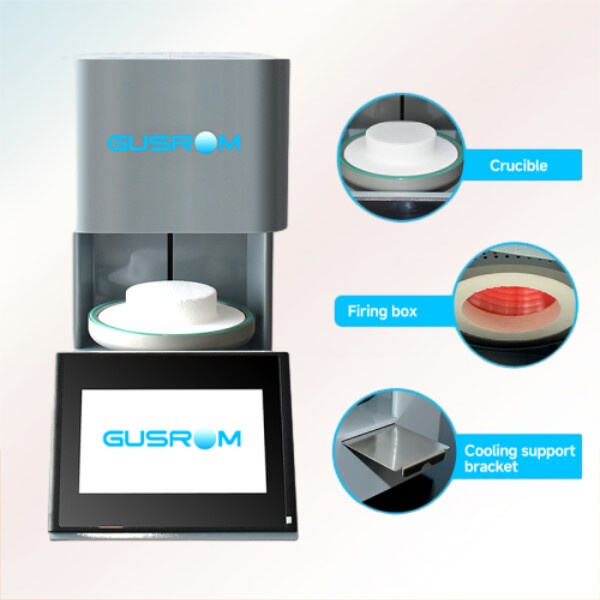

For a dental laboratory it is crucial for them to have a state of the art porcelain furnace that is capable of creating strong long lasting porcelain restorations. For example, a reliable furnace, such as those available form Gusrom, not only boils porcelain evenly, but also exactly, so that no mistake or weak line will be observed in the resulting work. This means that patients can enjoy secure and snug-fitting dentures for a long time.

Dental lab porcelain furnaces are vital to the production of dental prosthetics. Without these equipment it would be impossible for dental technicians to form and shape porcelain into exact shapes in order to fit a patient's mouth. This could lead to ill-fitting prosthetics, which can be painful for the patient and can also cause damage to the patient's teeth. With Gusrom high quality porcelain ovens, dental laboratories can have confidence that they are producing the highest performance dental prosthetics possible for their patients.

Recent features of dental lab porcelain furnace technology have significantly eased the process for dental labs to produce exceptional dental prosthetics. Contemporary furnaces by companies like Gusrom include digital controls that let techs control and watch the temperature in the furnace. To do this, the porcelain is placed under high pressure and forced through the mold to heat the porcelain evenly and reliable, so as to get strong, hard dental restorations with perfect fit in the patient oral cavity.