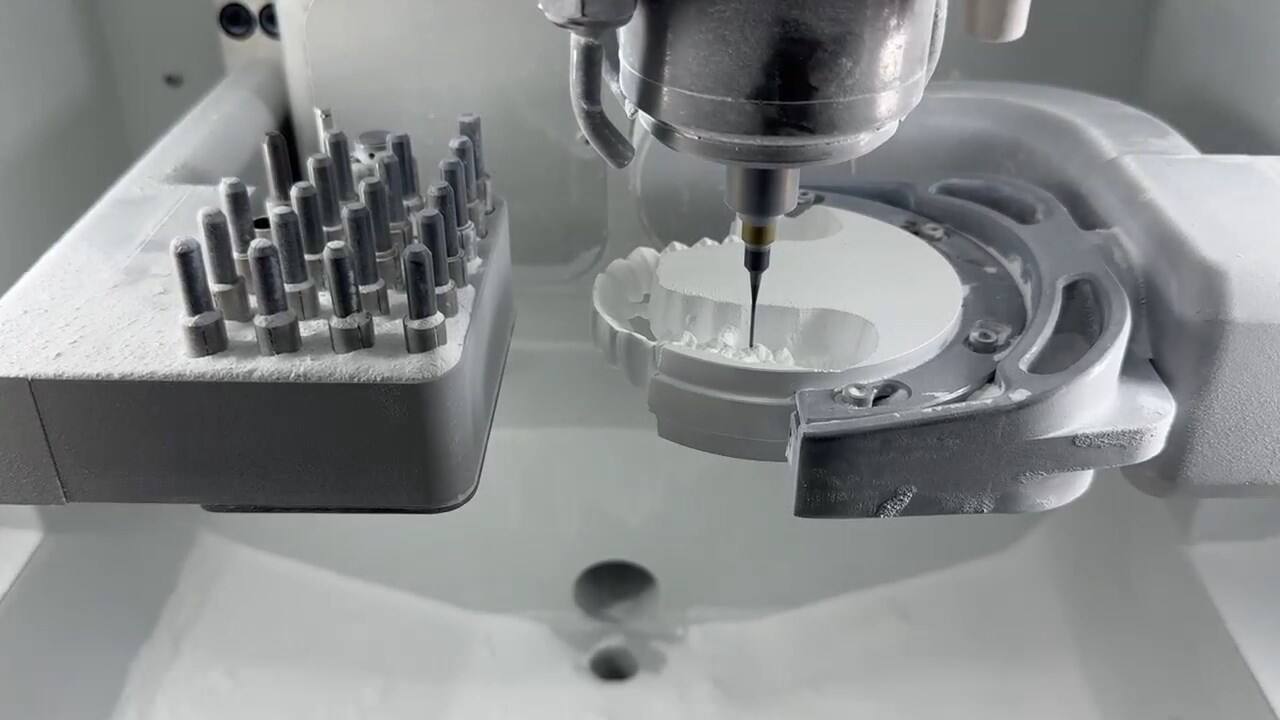

Dry & Wet Dental Milling Machine

Flexible Processing Modes:

Combining dry and wet cutting, this machine allows for seamless switching between dry and wet modes, tailored to the processing characteristics of different materials without requiring equipment changes. This machine meets the demands of fine engraving of zirconia in dry environments, as well as wet cutting of coolant-assisted materials such as glass ceramics, making it suitable for concurrent multi-material processing.

Strong Material Compatibility:

It can process a wide range of dental restoration materials, including zirconia, glass ceramics, titanium discs, cobalt-chromium alloys, wax, PMMA, and PEEK, covering a wide range of processing needs, from single crowns to multi-unit bridges.

High Precision:

These machines are typically equipped with a high-precision spindle and advanced motion control systems. These machines boast an 2500-watt, 60,000-rpm spindle and achieve repeatability of up to 5 microns, ensuring high-precision processing of denture restorations. The resulting dentures meet the highest standards in terms of size, shape, and surface quality.

High Machining Efficiency:

Equipped with a high-power spindle system, it supports high speeds, such as an ultra-high 60,000 RPM. This allows for extremely fast cutting while maintaining excellent power stability, shortening machining time and improving production efficiency. The machine is equipped with a 21-station automatic tool magazine and an integrated tool wear prediction algorithm, enabling real-time diagnosis of tool status and prompt replacement.

Reasonable Structural Design:

A five-axis rigid structure, combined with material-specific fixtures, creates a highly rigid machining environment, effectively suppressing vibration and deformation. This makes it particularly suitable for 90° vertical precision engraving of complex anatomical features, such as occlusal and interproximal surfaces. Furthermore, the machine's compact industrial design makes it suitable for both space-constrained chairside environments and high-volume production studios.

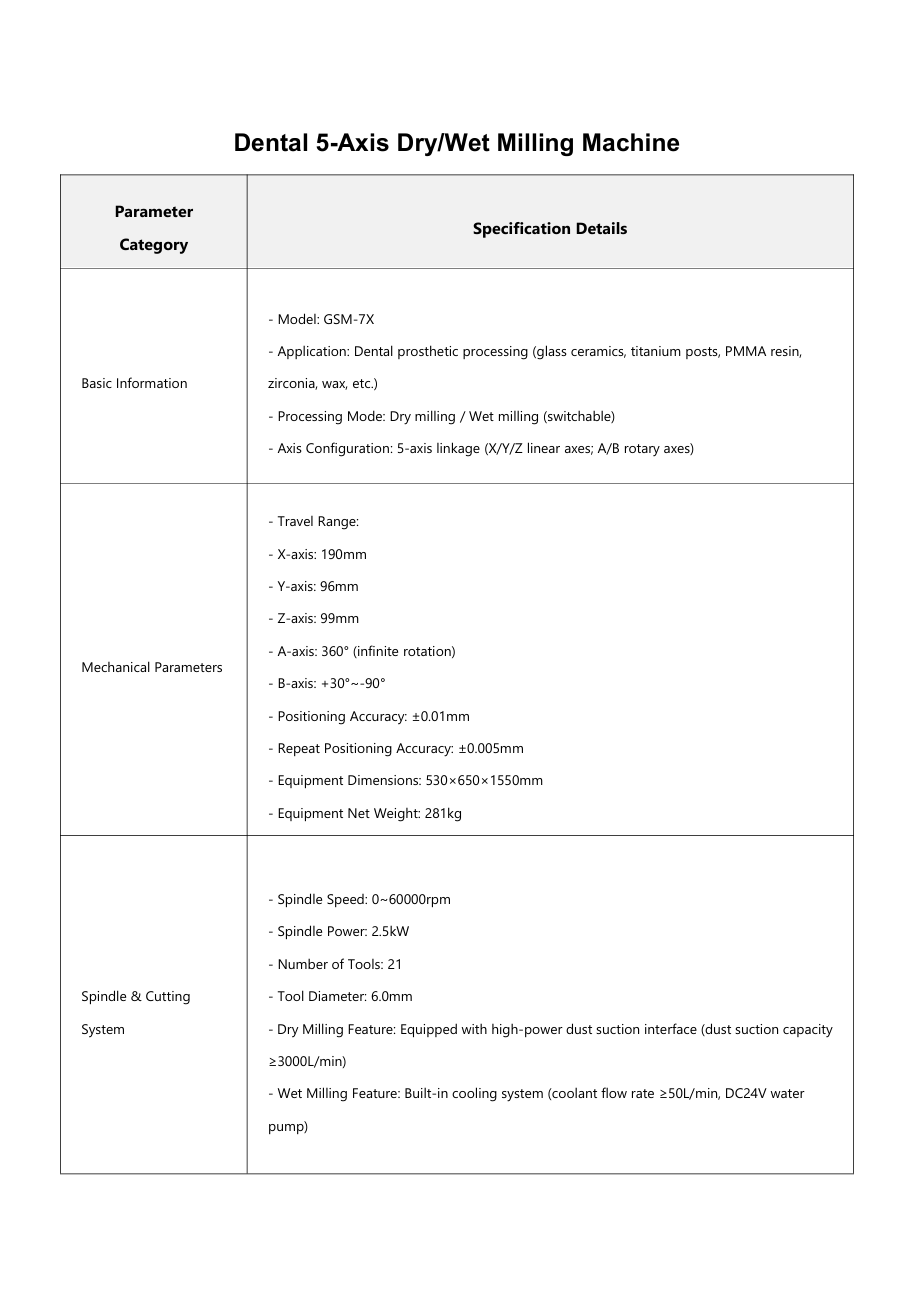

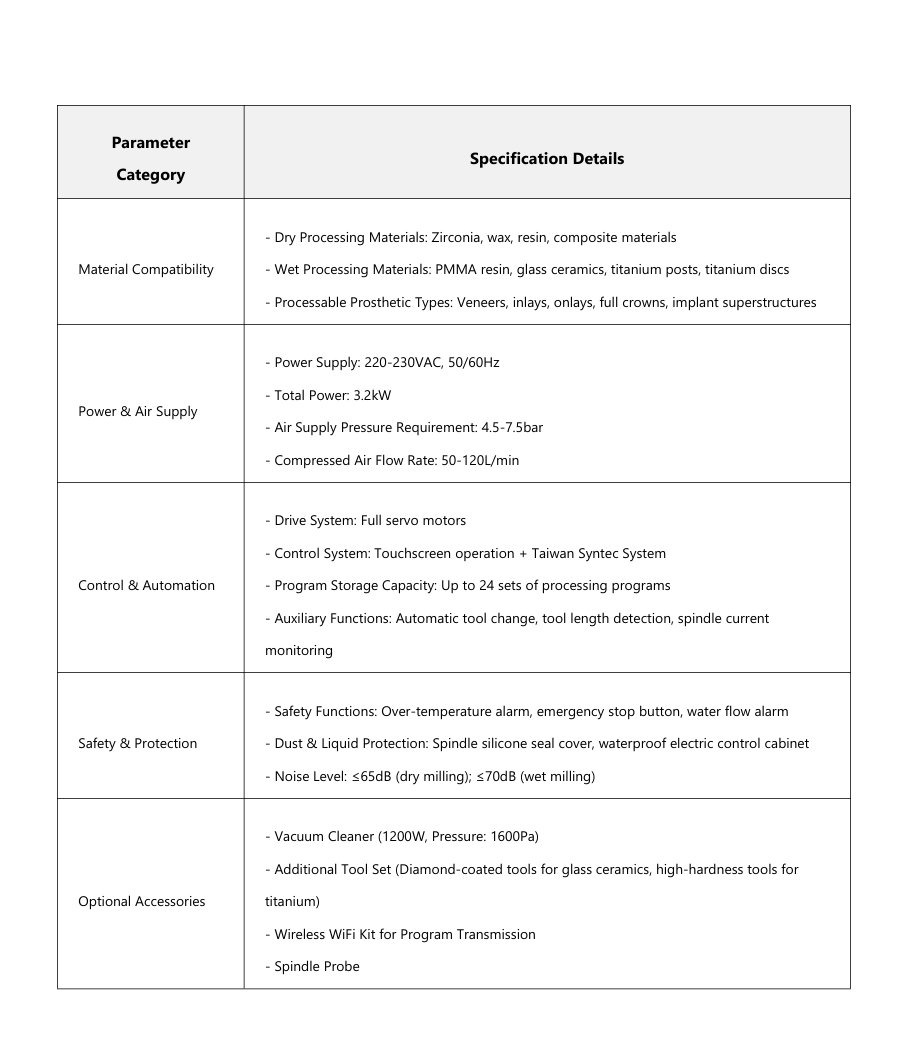

| Axis: | 5-axis linkage |

| Dry machining materials: | Zirconia, wax, resin, composites |

| Wet machining materials: | PMMA resin, glass ceramic, titanium posts, titanium discs |

| Processable denture types: | Veneers, inlays, onlays, crowns, and implant-mounted prostheses |

| Wet milling features: | Built-in cooling system (coolant flow ≥ 50 L/min, DC 24V pump) |

| Stroke range: | X/Y/Z: 190°-96°-99° A: 360° B: +30°-90° |

| Spindle speed: | 0-60,000 rpm/2.5 kW |

| Drive: | Full servo motor |

| Tools: Number: | 21 |

| Diameter: | 6 mm |

| Fixture position for Emax and pre-milled : | 6 positions for C14, 3 positions for pre-milled |

| Dimensions: | 530*650*1550 mm |

| Machining accuracy: | ±0.01 mm |

| Required air pressure: | 4.5-7.5 bar |

| Compressed air flow: | Approximately 120 L/min |

| Power: | 3.2 kW |

| Power supply: | 220-230V AC, 50/60Hz |

| Net weight: | 281kg |