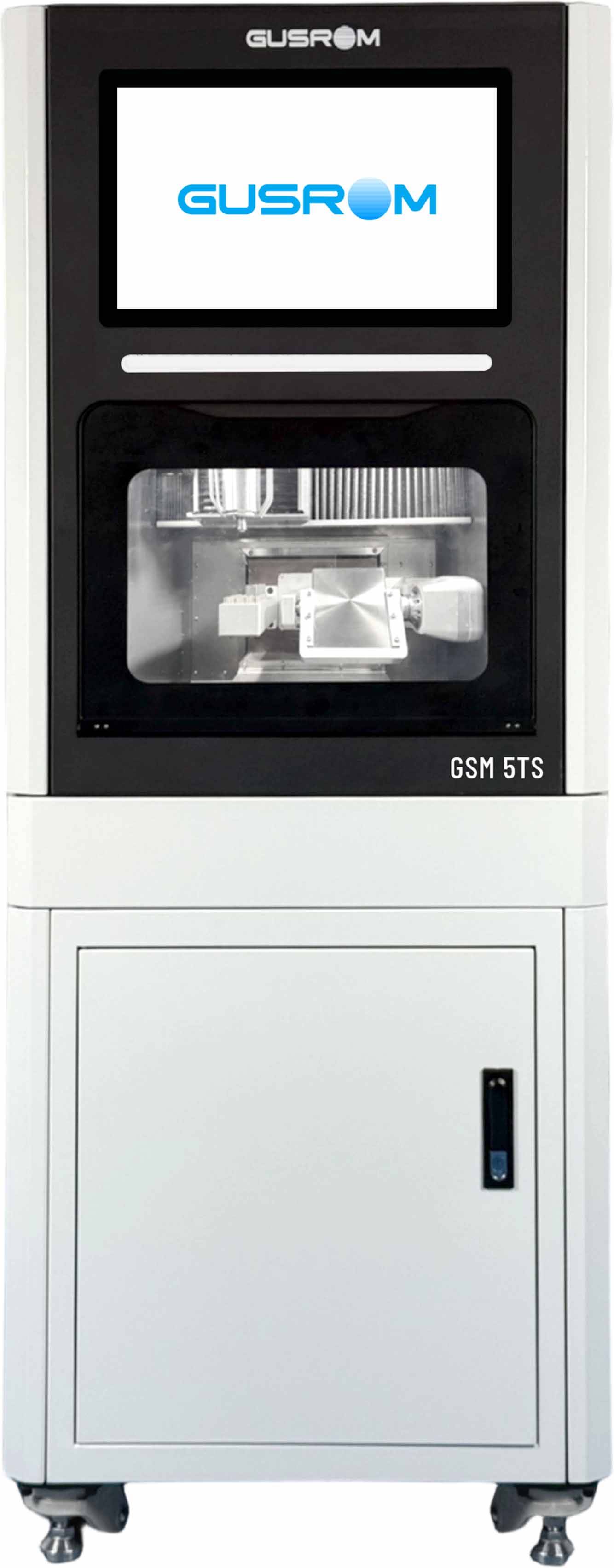

Dental Wet Milling Machine

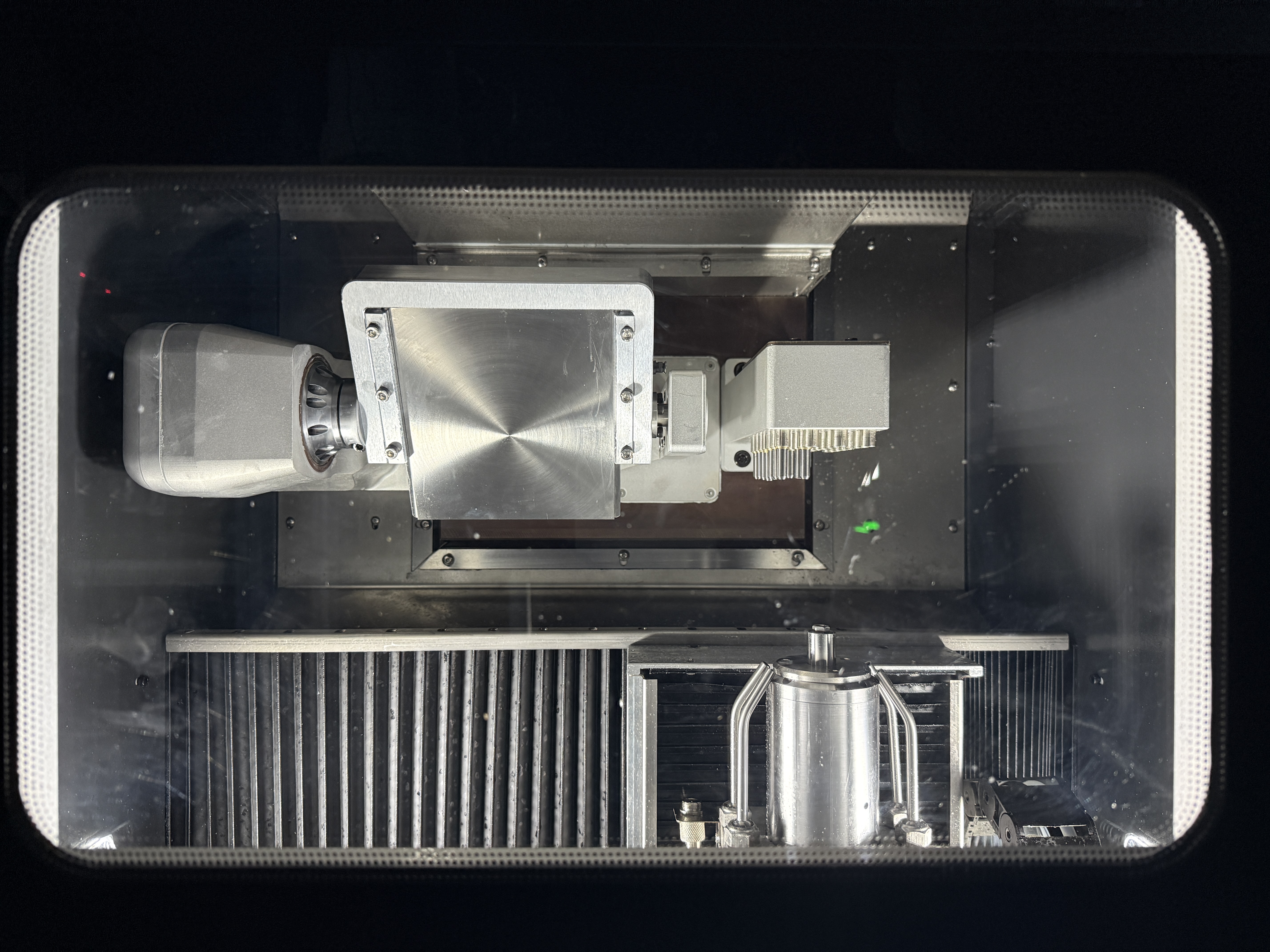

Five-Axis Precision Technology:

Featuring synchronized movement of three linear axes (X, Y, Z) and two rotary axes, the tool can be positioned at any 3D angle. This eliminates repeated clamping, delivering high-precision machining for complex anatomical crowns, customized abutments and other intricate curved surfaces.

Extreme Structural Rigidity:

Constructed from international-standard Meehanite cast iron with quenching and tempering reinforcement, the machine maintains zero deformation for up to 10 years. Its classic gantry structure, seamlessly welded interior and heavy-duty CNC milling base ensure outstanding long-term stability.

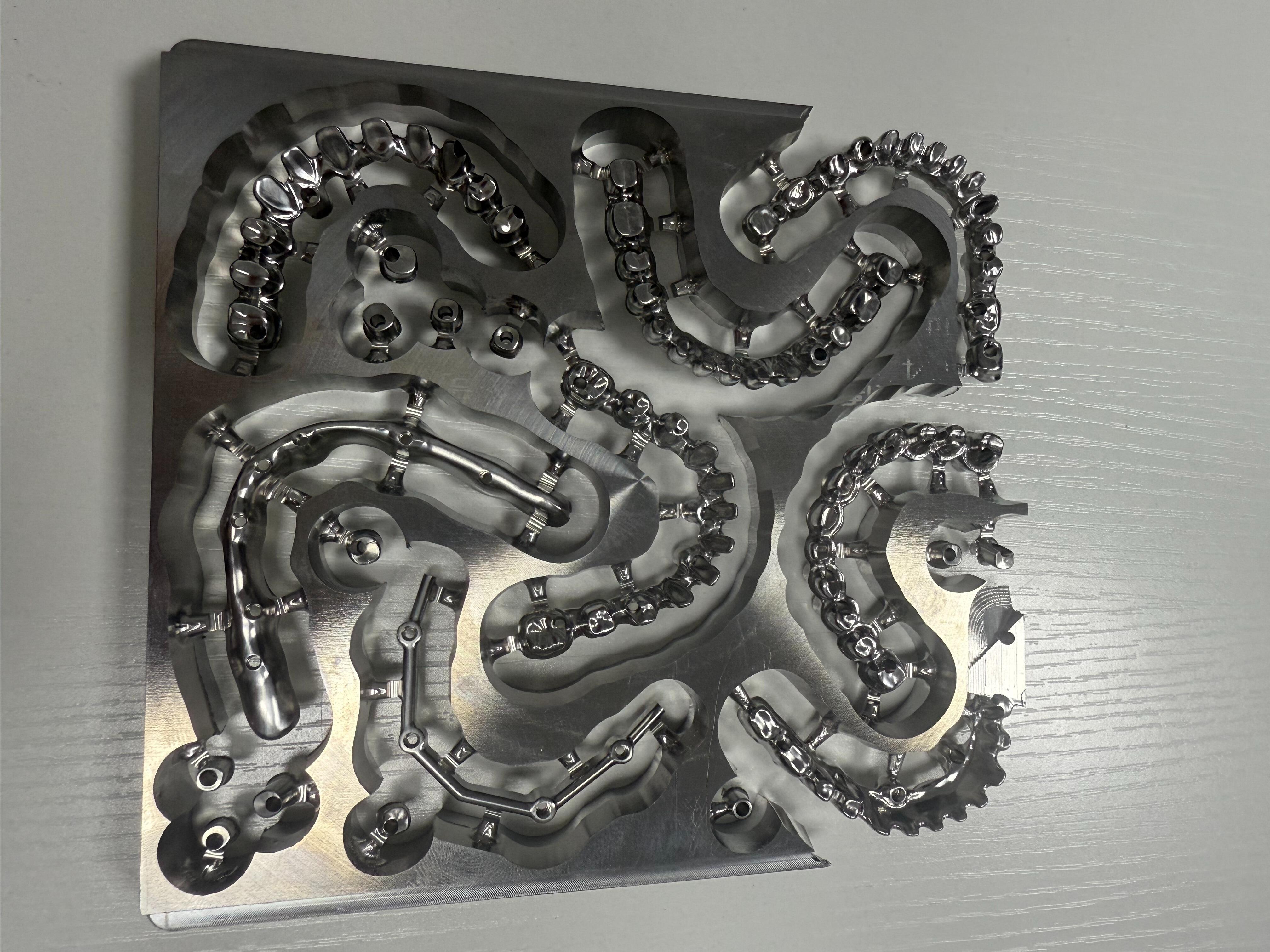

High Material Efficiency:

The dedicated fixture accommodates large 140×150mm square plates, milling 8+ bridges per block. Material utilization is improved by over 30% compared with traditional circular plates, greatly reducing material waste.

Wide Material Compatibility:

Equipped with a high-rigidity spindle and professional tools, it processes high-hardness dental materials including titanium alloys. Supporting a full range of restorations, it enables fast switching between single crowns and full denture frameworks.

| Item | Specification |

| Number of Axes | 5-axis |

| Cutting Method | Wet Milling |

| Cutting Materials | 140*150 titanium discs, round titanium disc, glass ceramics, titanium posts, etc. |

| Processing Types | Veneers, inlays, onlays, crowns, implant-mounted restorations, etc. |

| Travel Range | X/Y/Z: 230-120-100° A: 360° B: -30° to +22° |

| Spindle Speed | 60,000 rpm/2.5 kW |

| Drive | Full Servo Motor |

| Milling burs | 28 pcs |

| Diameter | 6 mm |

| Dimensions | 660*820*1640 mm |

| Machining Accuracy | ±0.01 mm |

| Required Air Pressure | 4.5-7.5 bar |

| Compressed Air Flow | Approximately 120 L/min |

| Power | 3.2 kW |

| Power Supply | AC 220-230V, 50/60 Hz |

| Net Weight | 585 kg |

Q: Are you a manufacturer or trading company

A:We are a OEM/ODM Professional manufacturing company in dentistry since 2010 with more than 14 years experience

Q: How long is your delivery time? if l want to customize the products, how long does it take

A: 1. lf the products are in stock, it is 5-7 working days.2. We can provide customized services for our customers. lt takes about 15 days

Q: How can l order

A:We will make quotation after you send us your purchase plan(including product name, model and quantity). lf you agree with the quotation, please send us your company name, address and telephone for goods delivery. We will make proforma invoice and inform you the payment way. Goods delivery details will also be informed accordingly

Q: How is your company's product after-sales service

A:The product warranty period is 12 months, we can provide lifetime maintenance, We have professional pre-sales and after-sales departments that can respond to you within 24 hours to resolve any technical issues if you have problem in using, you can describe the problem details, we will ask technician to give your solution. Free spare parts can be provided if necessary

Q: What's your product

A: We have full zirconia series including White blocks; SHT zirconia blocks; UT zirconia, etc. We also provide other milling solution materials such as Multilayer PMMA, Mono PMMA, Transparent PMMA, WAX, miling burs, fast sintering furnace, glaze/stain kit and digital design service etc