Built-in cooling system,Full servo motors Drive System, Proprietary industrial-grade CNC control system , Up to 24 sets of processing programs, Automatic tool change, tool length detection, spindle currentmonitoring Auxiliary Functions

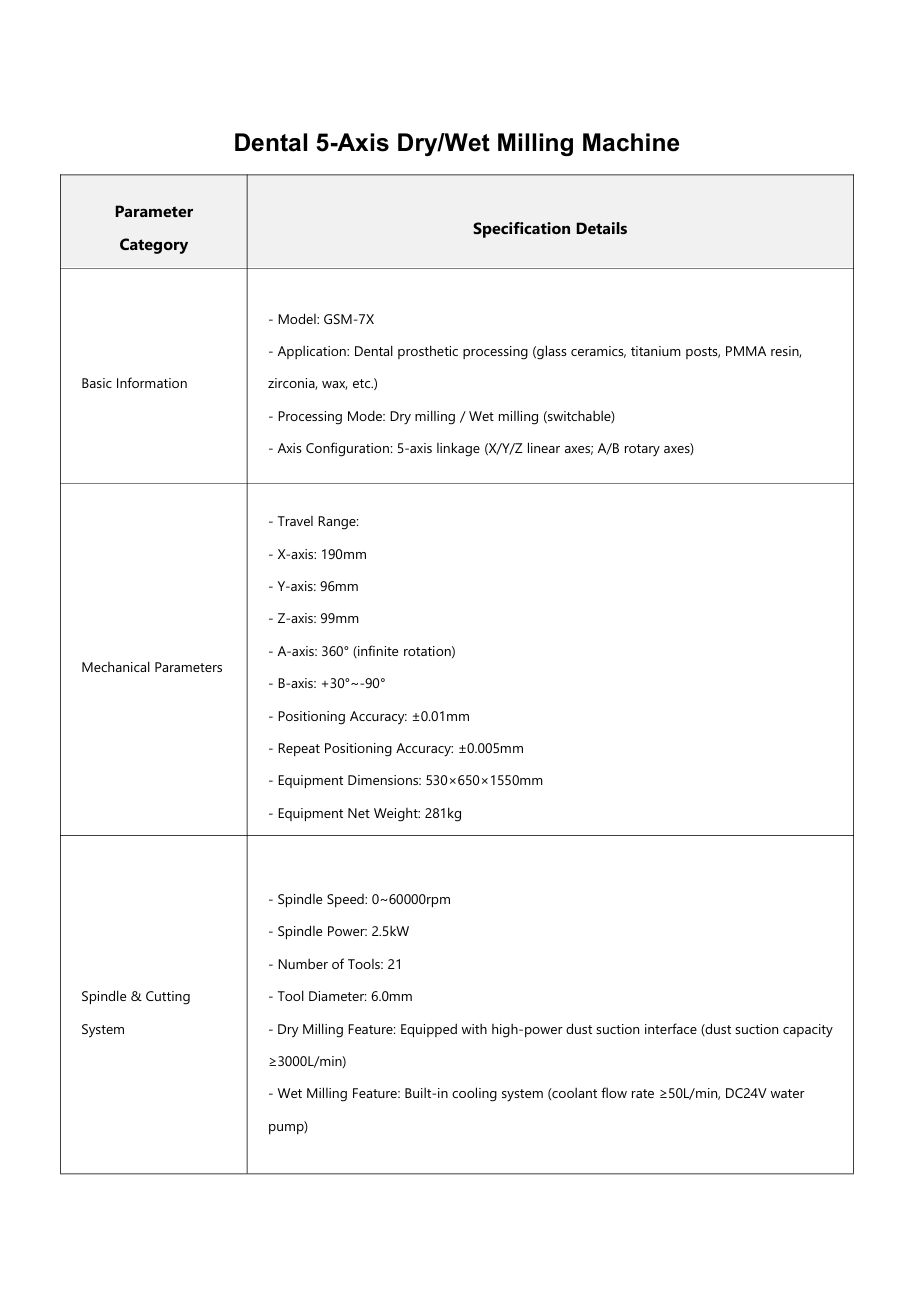

| Item | Specification |

|---|---|

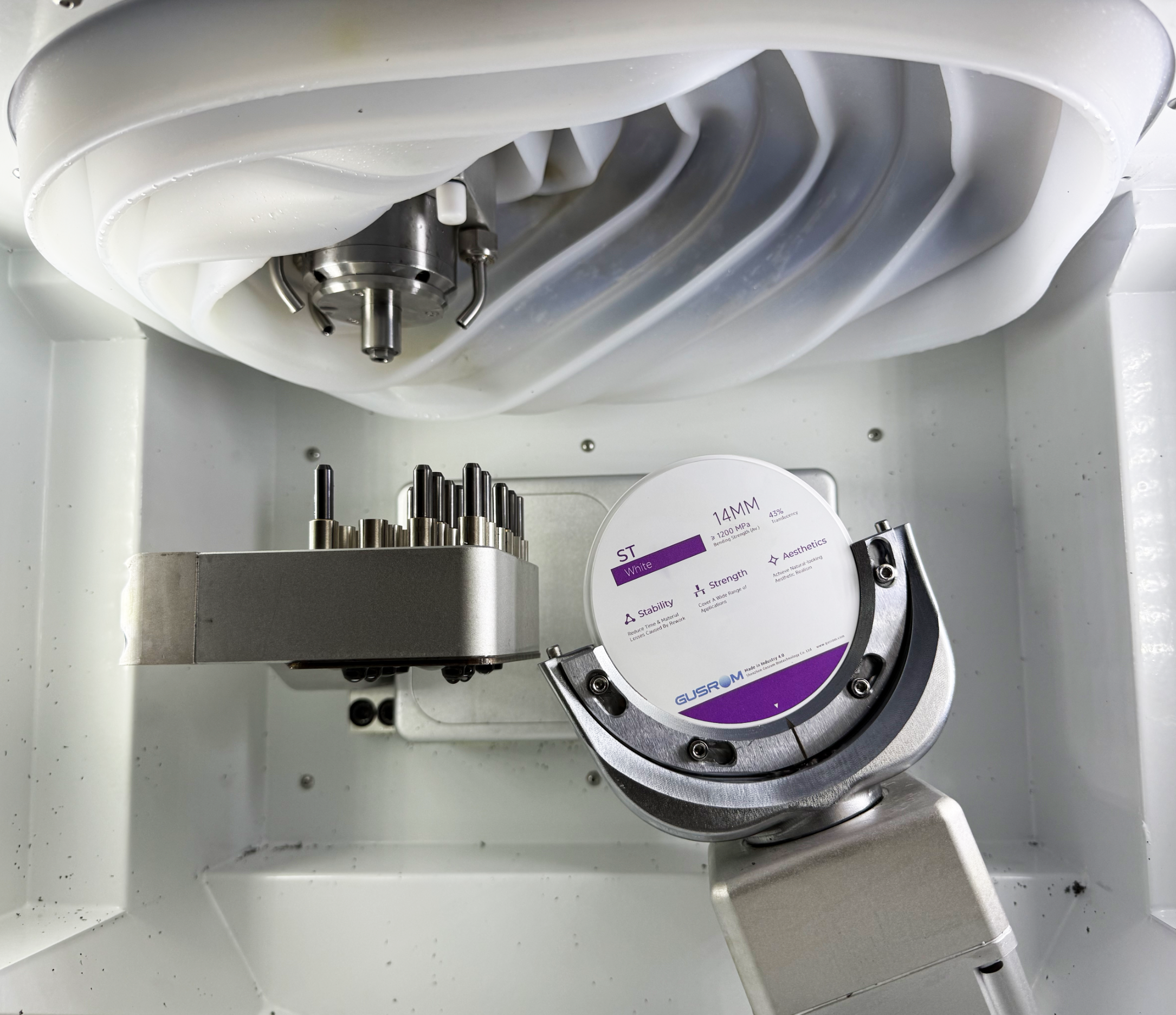

| Model | GSM-7X |

| Application | Dental prosthetic processing (glass ceramics, titanium posts, PMMA resin, zirconia, wax, etc.) |

| Processing Mode | Dry milling / Wet milling (switchable) |

| Axis Configuration | 5-axis linkage (X/Y/Z linear axes; A/B rotary axes) |

| Travel Range | X: 190/Y: 96/Z: 99 mm; A: 360° (infinite rotation)/B: +30°~-90° |

| Positioning Accuracy | ±0.01mm |

| Repeat Positioning Accuracy | ±0.005mm |

| Equipment Dimensions | 530×650×1550mm |

| Equipment Net Weight | 281kg |

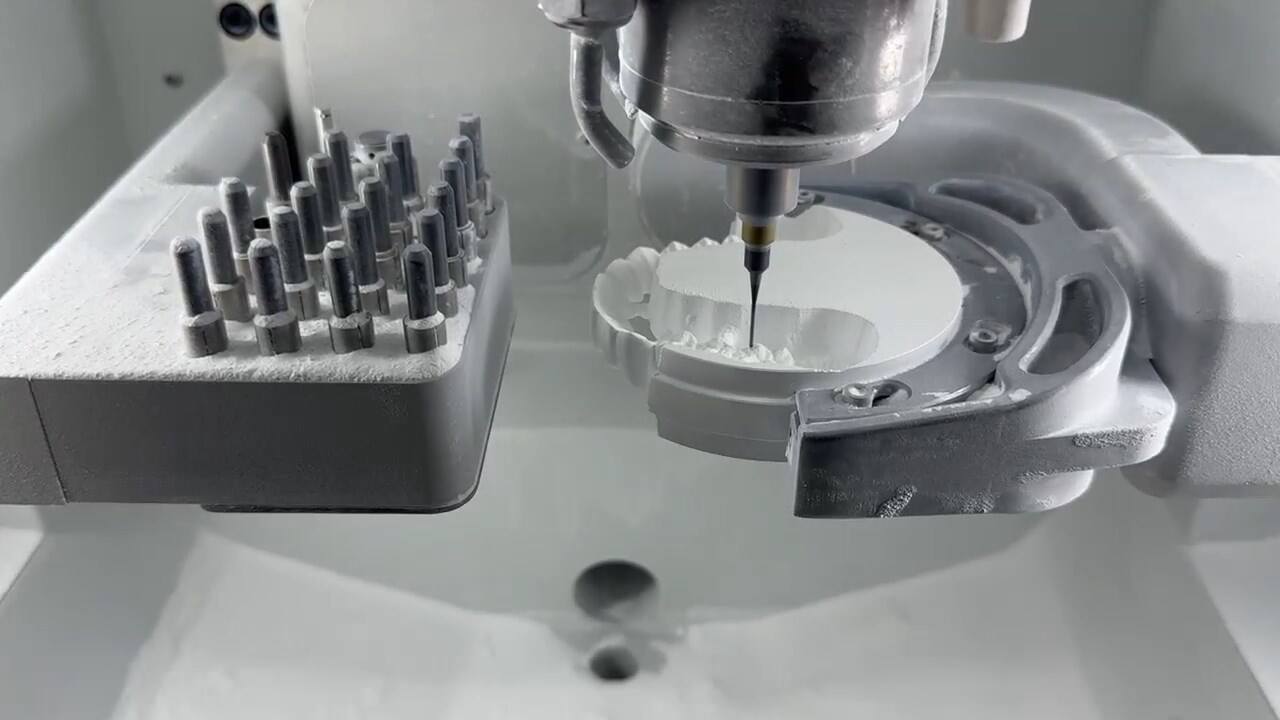

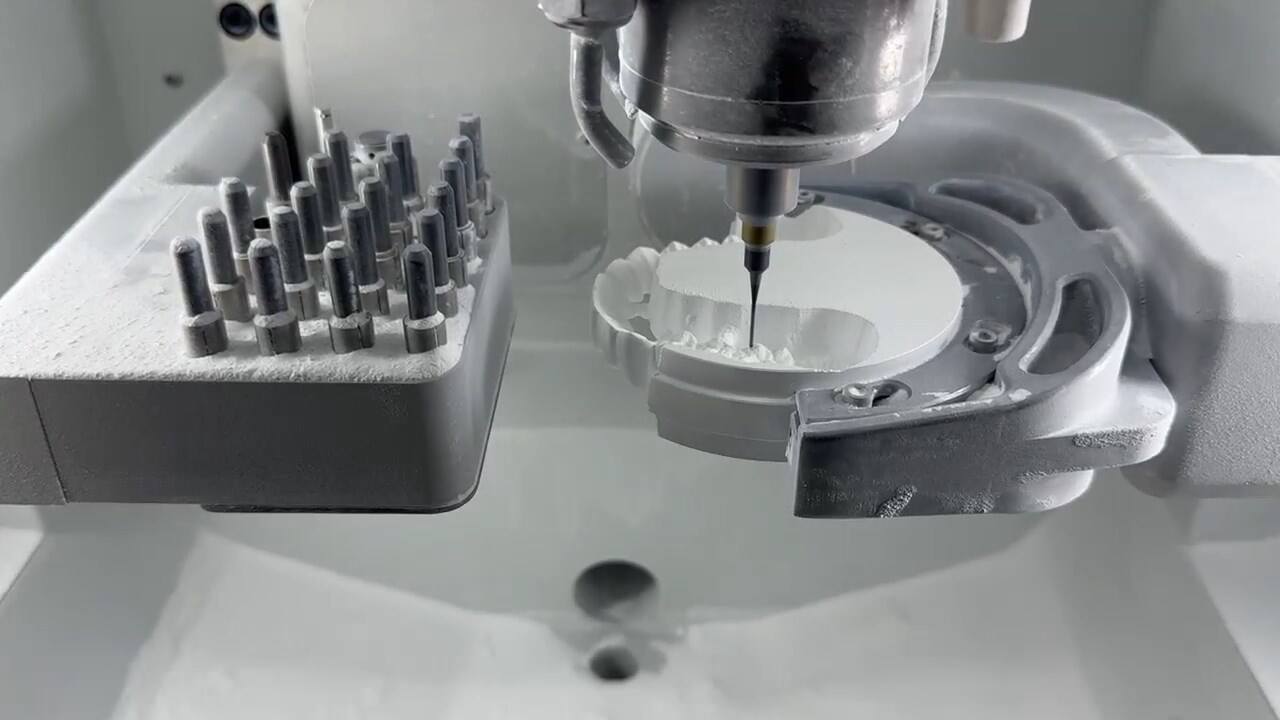

| Spindle Speed | 0~60000rpm |

| Spindle Power | 2.5kW |

| Number of Tools | 21 |

| Tool Diameter | 6.0mm |

| Dry Milling Feature | Equipped with high-power dust suction interface (dust suction capacity ≥3000L/min) |

| Wet Milling Feature | Built-in cooling system (coolant flow rate ≥50L/min, DC24V water pump) |

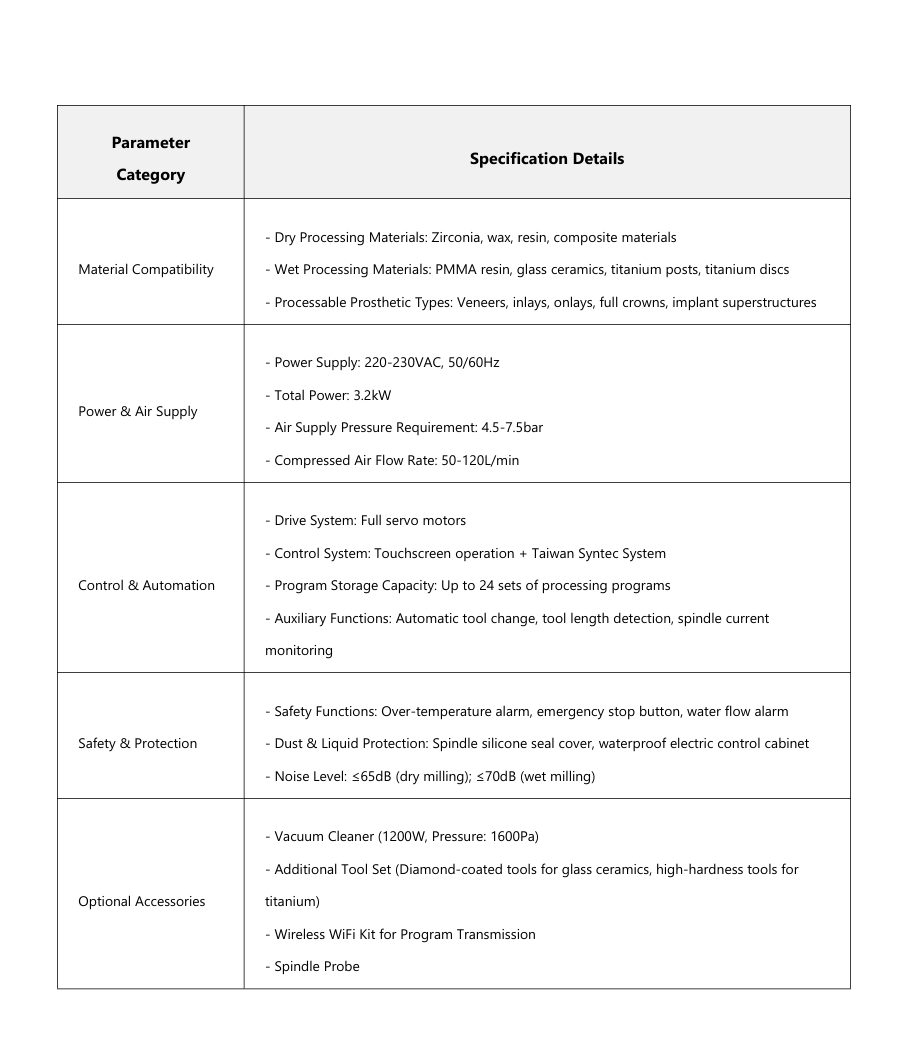

| Dry Processing Materials | Zirconia, wax, resin, composite materials |

| Wet Processing Materials | PMMA resin, glass ceramics, titanium posts, titanium discs |

| Processable Prosthetic Types | Veneers, inlays, onlays, full crowns, implant superstructures |

| Power Supply | 220-230VAC, 50/60Hz |

| Total Power | 3.2kW |

| Air Supply Pressure Requirement | 4.5-7.5bar |

| Compressed Air Flow Rate | 50-120L/min |

| Drive System | Full servo motors |

| Control System | Touchscreen operation + Taiwan Syntec System |

| Program Storage Capacity | Up to 24 sets of processing programs |

| Auxiliary Functions | Automatic tool change, tool length detection, spindle current monitoring |

| Safety Functions | Over-temperature alarm, emergency stop button, water flow alarm |

| Dust & Liquid Protection | Spindle silicone seal cover, waterproof electric control cabinet |

| Noise Level | ≤65dB (dry milling); ≤70dB (wet milling) |

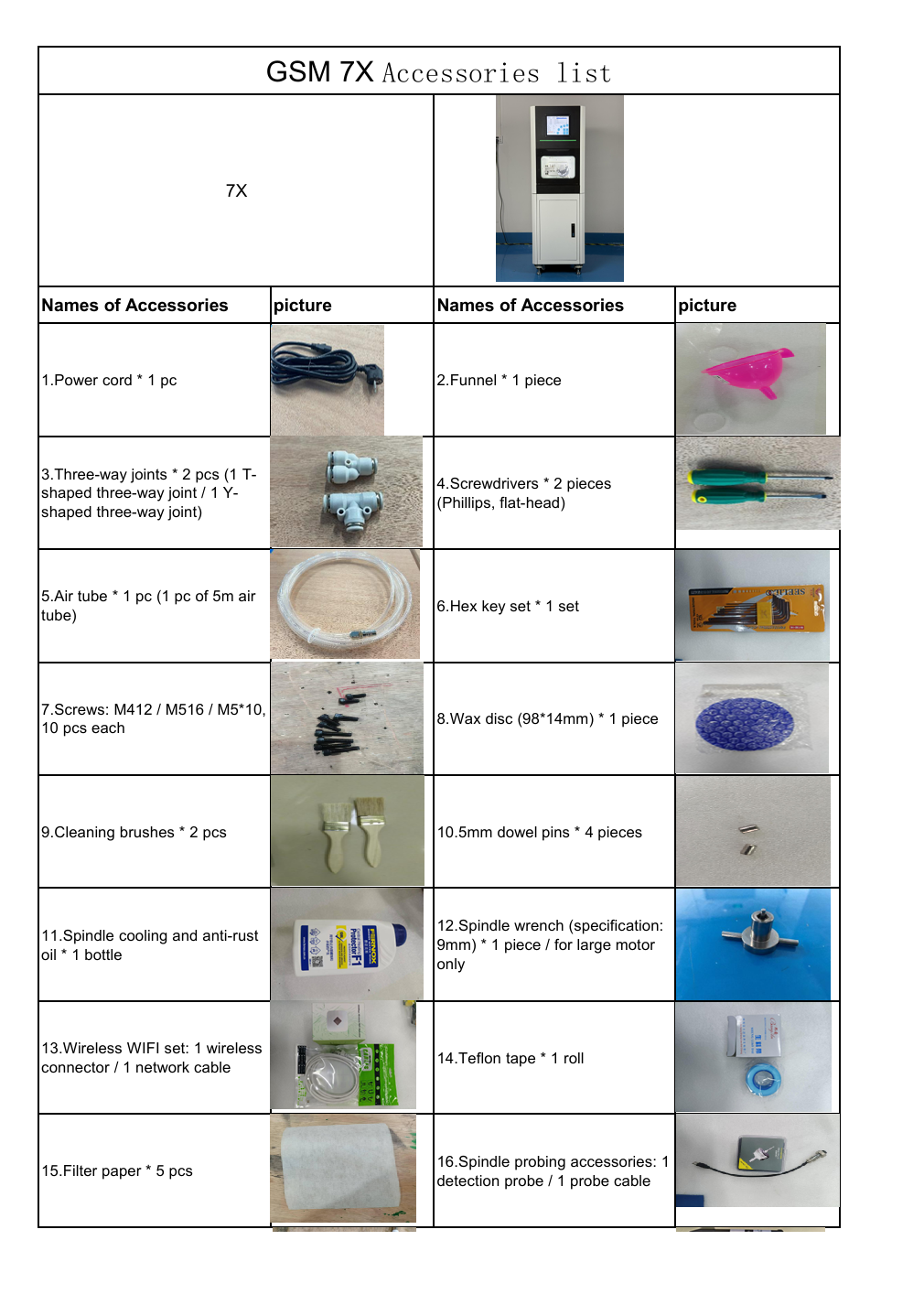

| Standard Accessories | Vacuum Cleaner (1200W, Pressure: 1600Pa); Additional Tool Set (Diamond-coated tools for glass ceramics, high-hardness tools for titanium); Wireless WiFi Kit for Program Transmission; Spindle Probe |

Q: Are you a manufacturer or trading company

A: We are an OEM/ODM professional manufacturing company focused on dental products, officially established in 2024. Our core technical and R&D team has over 10+ years of industry experience in dentistry, ensuring high-quality product development and production.

Q: How long is your delivery time? if l want to customize the products, how long does it take

A: 1. lf the products are in stock, it is 5-7 working days.2. We can provide customized services for our customers. lt takes about 15 days

Q: How can l order

A:We will make quotation after you send us your purchase plan(including product name, model and quantity). lf you agree with the quotation, please send us your company name, address and telephone for goods delivery. We will make proforma invoice and inform you the payment way. Goods delivery details will also be informed accordingly

Q: How is your company's product after-sales service

A:The product warranty period is 12 months, we can provide lifetime maintenance, We have professional pre-sales and after-sales departments that can respond to you within 24 hours to resolve any technical issues if you have problem in using, you can describe the problem details, we will ask technician to give your solution. Free spare parts can be provided if necessary

Q: What's your product

A: We have full zirconia series including White blocks; SHT zirconia blocks; UT zirconia, etc. We also provide other milling solution materials such as Multilayer PMMA, Mono PMMA, Transparent PMMA, WAX, miling burs, fast sintering furnace, glaze/stain kit and digital design service etc