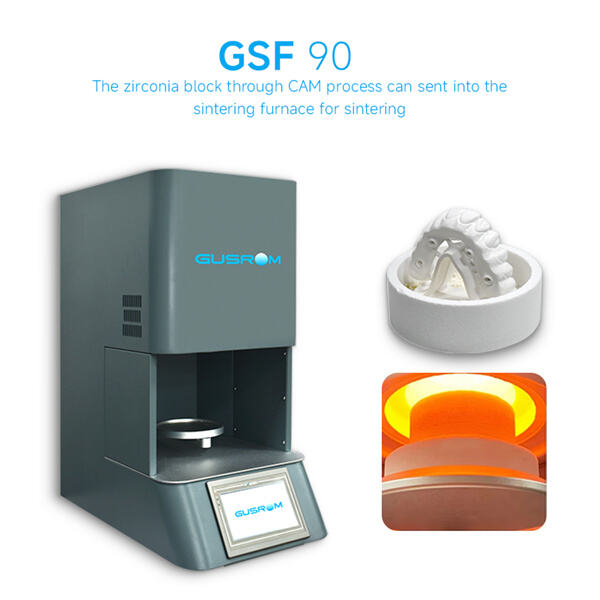

Knowledge of zirconia sintering is necessary in order to make durable and strong dental restorations. Sintering is like baking a cake – you put zirconia powder in the oven at high temperatures until it solidifies into a solid, strong material. This sintering shrinks the zirconia powder and hardens it.

It is also desirable to obtain the best sintering conditions for zirconia in order to make quality dental restorations. Through exact temperature and time control during sintering dental technicians are able to obtain the ideal combination of strength and durability in zirconia restorations. This means that the prosthetics are durable and will withstand the test of time and give patients a great smile for a long time.

Strengthening and toughening Gusrom 4D X ML Zirconia Block-100% TOSOH Multilayer Zirconia through sintering are also important in producing zirconia as long-lasting dental restorations. Zirconia is super strong and tough when properly sintered. This allows patients to wear their dental restorations for extended periods without worrying that they’ll break or chip.

An influence of temperature and time when firing of zirconia are not be underestimated. The sintering temperature of zirconia points out its ultimate strength and stability. The hotter you make it, the harder it is. The sintering time and temperature are controlled precisely in the sintering procedure, thus dental laboratories may have the zirconia batches that are fully sintered.

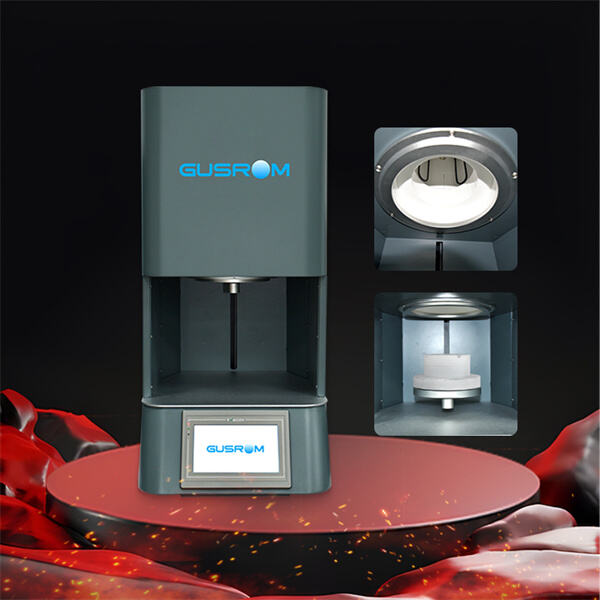

Thanks to advances in zirconia sintering procedures, it has never been easier to produce robust and long-lasting dental restorations. Modern techniques for sintering zirconia go beyond what was feasible just a decade ago, enabling dentists and labs to produce restorations with superior strength and endurance. Thanks to these advances, our dental restorations are doing wonders for patients who never believed they’d have a smile they could feel good about showing off.